Advantages of C Purlins:

– Ability to spanlength

– Purlin erection is easierthan others

– Fast to erect and easy handling

– No side drilling/cutting required

– Assured dimensions and straightness

– High durability, versatility and uniform quality

– Low transportation cost due to decreased weight

– Close tolerances onsectional sizes due to process of cold roll forming

C Purlins

C Purlins are horizontal structure’s that are used to support the load from the roof deck or the sheathing. The plane surface of this purling on one side has made it a preferred material for cladding due to its easy installation on concrete structures or steel. Ourrange purlins are light in weight and perfect for simple span construction.

Advantages of Z Purlins:

– Ability to span length

– Saving in Steel up to 40%

– Fast to erect and easy handling

– No side drilling/cutting required

– Assured dimensions and straightness

– Purlin erection is easierthan others

– Saving in construction cost up to 30%

– High durability,versatility and uniform quality

– Low transportation cost due to reduced weight

– Close tolerances on sectional dimensions owing to process of cold roll forming

– Savingup to 35-40% in weight and 20% in cost when compared to hot rolled purlins

Z Purlins

Z Purlins are made using cold-formed or rolled sheets for supporting roof. The flexible shape of thesebeams facilitates various designs solutions. These purlins are extensively used in huge roofing solutions such asgo-downs, workshops, industrials sheds and many more. The range is known for saving up to 50%on structural sheet in comparisonwith hot rolled angles. Our purlins are crisp and clean in design and donotallow the scopeinaccurate lengths.

Advantages of Sigma Purlin:

– Optimum quality

– Easy installation

– High tensile strength

– Abrasion & corrosion resistance

Sigma Purlin

Sigma purlins are designed for cost effectiveness & better Stability. Sigma Purlin requires less support accessories. It helps to increase the Election speed with less time Sigma purlins are designed with code of – BS EN 1993-1-3:2006.

Puff Panel Make:

– Jindal Mectech

– Thickness- 30MM/50MM/100MM

Puff Panel

We do supply & Erect the Puff panel for the Industries and we are the dealers for the firm developing next-generation PUF Panels & Cold Storage Room. Our line of products is made from premium grade material acclaimed for its strength, durability, properties and economical price range.

Sheet and accessories:

– Ridges,Flashing & Gutters

– Industrial Roofing & cladding

– Ware house

DRD

Architectural & Structural

Execution of 3D modelling, Detailing – Fabrication/Shop & As built Drawings, BIM Reports, 3D live Virtual reality, Structural Design and analysis

Primary tools: Revit, Tekla & Staad Pro

MEP

HVAC load calculations, 3D modelling , Detailing, BIM reports

Plant Engineering

PID, 3D modelling, Isometrics, GA drawings, Supports, MTO’s and pipe stress analysis. BIM Connect from PID to Execution Drawings (Workflow adoption on design Stage)

Primary tools: AutoCAD Plant 3D, PDS and PDMS

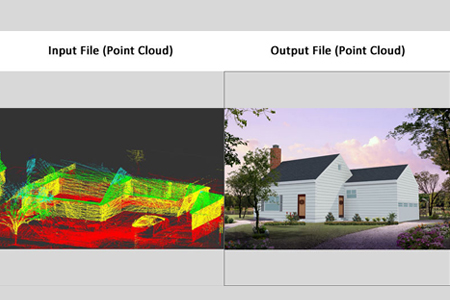

Point Cloud Conversion

Conversion of point cloud data in industry best accuracy range upto 97%.

Tools: Recap, Revit, AutoCAD Plant 3D